Santa Clara, California, January 2026, According to parliament news that international attention to Intel as the company continued grappling with prolonged production challenges, underscoring how Intel manufacturing delays remain a defining issue for the semiconductor giant this year.

The situation arrives at a critical moment for Intel, which is navigating an ambitious transformation aimed at restoring technological leadership while responding to investor expectations, government policy initiatives, and intensifying global competition in advanced chip production.

A Pivotal Year for Intel’s Manufacturing Strategy

The year 2026 represents a turning point in Intel’s long-term manufacturing strategy. After years of declining market share and execution missteps, the company committed to rebuilding its fabrication capabilities through unprecedented capital investment.

Despite that commitment, Intel manufacturing delays have complicated progress, raising questions about execution speed and the feasibility of meeting revised production milestones. For a company that once set the industry’s pace, timing has become a central concern.

The Complexity of Rebuilding Advanced Fabrication

Modern semiconductor fabrication is among the most complex industrial undertakings in the world. Each new process node requires years of development, testing, and fine-tuning across thousands of variables.

Intel manufacturing delays reflect the inherent difficulty of simultaneously upgrading facilities, training specialized talent, and maintaining output from legacy processes. Even minor disruptions can cascade into months-long schedule adjustments.

Supply Chain Pressure Remains a Core Constraint

Global semiconductor supply chains remain fragile. Highly specialized tools, including advanced lithography equipment, depend on a narrow group of suppliers operating at full capacity.

Intel manufacturing delays have been exacerbated by staggered equipment deliveries and component shortages, limiting the company’s ability to ramp production as planned. These constraints highlight how manufacturing leadership now depends as much on logistics as on engineering.

Competitive Dynamics in a Crowded Market

Intel operates in a semiconductor market defined by rapid innovation and fierce competition. Rivals leveraging outsourced manufacturing models have moved quickly to deliver advanced chips for artificial intelligence, data centers, and high-performance computing.

As Intel manufacturing delays persist, competitors gain an advantage in securing long-term customer commitments. In this environment, predictable delivery schedules often weigh as heavily as performance benchmarks.

Investor Scrutiny and Market Expectations

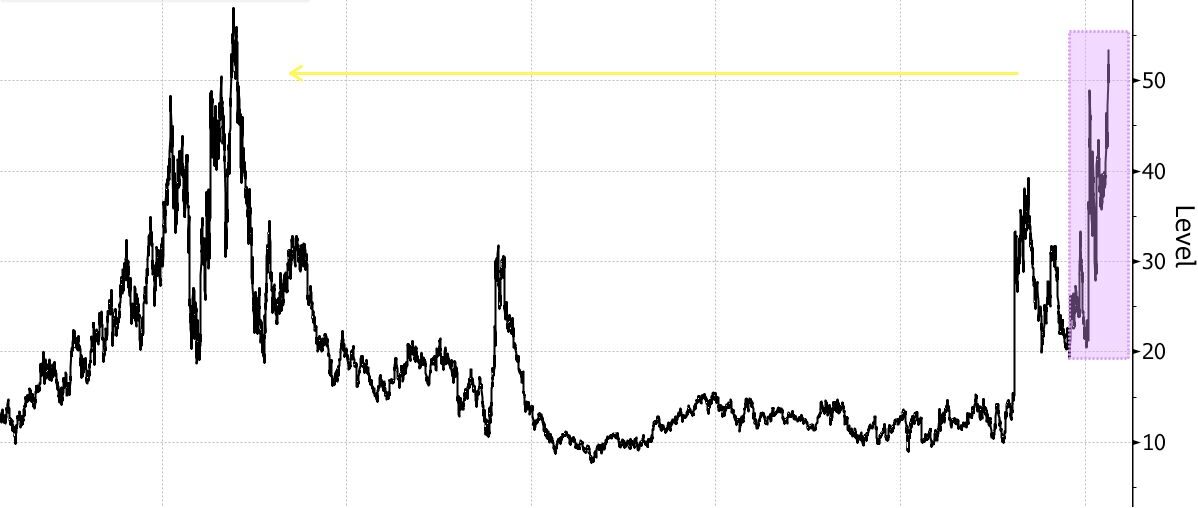

Financial markets closely monitor manufacturing execution as a proxy for strategic credibility. Investors understand the scale of Intel’s transformation, but patience is finite.

Intel manufacturing delays have contributed to volatility in market sentiment, as shareholders assess whether long-term investment will translate into competitive advantage. Clear progress milestones are increasingly viewed as essential to restoring confidence.

Customer Relationships and Contract Timelines

Intel supplies chips to a wide range of enterprise, government, and consumer technology partners. These customers depend on reliable delivery timelines to plan their own product launches and infrastructure upgrades.

Intel manufacturing delays introduce uncertainty into these relationships. While long-standing partnerships provide resilience, extended unpredictability can influence future procurement decisions.

Financial Impact of Prolonged Delays

Delays in manufacturing carry financial consequences beyond missed revenue opportunities. Idle equipment, workforce inefficiencies, and rescheduled production runs increase operating costs.

Intel manufacturing delays have heightened scrutiny of cost management, particularly as the company continues investing billions in new facilities. Balancing long-term investment with near-term financial discipline remains a delicate task.

Leadership Messaging and Internal Alignment

Intel’s leadership has consistently emphasized patience and persistence, framing current challenges as part of a multi-year rebuilding effort rather than a short-term setback.

One executive communication summarized the approach:

“This transformation requires discipline, focus, and time, but the foundation we are building will define Intel’s future.”

This single statement encapsulates how Intel manufacturing delays are positioned internally as obstacles to overcome rather than signals of failure.

Workforce Challenges in Advanced Manufacturing

Advanced semiconductor manufacturing depends on a highly specialized workforce. Engineers, technicians, and process specialists require years of training to operate next-generation fabrication tools.

Intel manufacturing delays have been compounded by competition for skilled labor, particularly as multiple companies expand domestic production capacity simultaneously.

Regional Economic Significance in California

Intel’s California operations remain central to the state’s technology ecosystem. Manufacturing activity supports thousands of direct and indirect jobs across engineering, logistics, and professional services.

Local officials are closely watching how Intel manufacturing delays may influence regional economic stability in 2026, particularly as public policy emphasizes domestic semiconductor resilience.

Government Policy and Domestic Production Goals

U.S. policy initiatives aimed at strengthening domestic chip production have placed Intel in a strategic position. These programs seek to reduce reliance on overseas manufacturing and improve national supply chain security.

Intel manufacturing delays complicate these objectives by extending timelines for new capacity, underscoring the challenge of rebuilding advanced manufacturing at scale.

Technology Roadmaps Under Pressure

Semiconductor roadmaps rely on precise coordination between design teams and fabrication facilities. When manufacturing timelines slip, entire product cycles can be affected.

Intel manufacturing delays place pressure on roadmap execution, increasing the risk of missed market windows and forcing adjustments across multiple business units.

Automation and Process Optimization Efforts

Intel continues to invest heavily in automation to improve yield, reduce error rates, and accelerate production cycles. These efforts are intended to create long-term efficiency gains.

Over time, such investments may help mitigate Intel manufacturing delays by increasing consistency and reducing dependence on manual intervention in complex processes.

Lessons from Past Industry Cycles

The semiconductor industry has experienced multiple cycles of expansion and contraction. Companies that successfully navigated previous downturns often did so by maintaining long-term investment discipline.

Intel manufacturing delays represent a test of whether institutional experience can offset current execution challenges in an industry that has grown more competitive and capital-intensive.

Long-Term Outlook Beyond 2026

Despite near-term challenges, Intel’s long-term ambitions remain substantial. The company continues to pursue leadership in advanced manufacturing, supported by significant capital resources and policy backing.

Intel manufacturing delays will ultimately be judged by whether they represent a temporary phase in a broader recovery or a structural limitation on competitiveness.

A Defining Moment for the Semiconductor Industry

Intel’s experience reflects broader realities facing global semiconductor manufacturing. Building advanced fabrication capacity is increasingly expensive, complex, and time-consuming.

The persistence of Intel manufacturing delays highlights how execution, rather than ambition, now defines success in the race for technological leadership.

Execution Will Define the Outcome

As 2026 unfolds, Intel stands at a crossroads. The company’s investments, workforce, and strategic vision position it for potential recovery, but progress depends on consistent execution.

The ongoing Intel manufacturing delays underscore a central lesson for the technology sector: in advanced manufacturing, resilience is built not only through capital and policy support, but through disciplined, sustained operational excellence.