Veldhoven, Netherlands — January — The trajectory of global chip demand has become a defining economic and technological issue this year, as governments, manufacturers, and investors reassess how advanced semiconductors are produced, distributed, and secured. At the center of this transformation stands ASML, whose technology underpins the most advanced chips powering artificial intelligence, defense systems, and critical digital infrastructure worldwide.

The semiconductor industry, long characterized by cyclical booms and downturns, is now navigating a structurally different phase. Demand is no longer driven solely by consumer electronics but by strategic, long-term needs tied to national security, industrial automation, and the global race for technological leadership.

A Structural Shift in Semiconductor Consumption

The nature of semiconductor consumption has evolved dramatically over the past decade. Earlier growth waves were dominated by smartphones, personal computers, and household electronics. Today, the drivers are far broader and deeper, encompassing artificial intelligence, cloud computing, electric mobility, and advanced medical technologies.

This shift has elevated the importance of manufacturing precision rather than sheer volume. As a result, global chip demand increasingly favors suppliers capable of enabling the smallest, fastest, and most energy-efficient chips. Advanced manufacturing tools, rather than raw silicon output, have become the critical bottleneck in the supply chain.

ASML’s Technological Gatekeeper Role

ASML’s role in this environment is unique. The company is the only manufacturer of extreme ultraviolet lithography systems, which are essential for producing chips at the most advanced process nodes. Without these machines, cutting-edge semiconductor production would effectively stall.

As global chip demand intensifies, ASML’s position as a technological gatekeeper has drawn heightened attention from policymakers and industry leaders. Decisions made in Veldhoven now carry implications for data centers in North America, automotive factories in Europe, and defense systems across Asia.

Capacity Constraints in a High-Demand Era

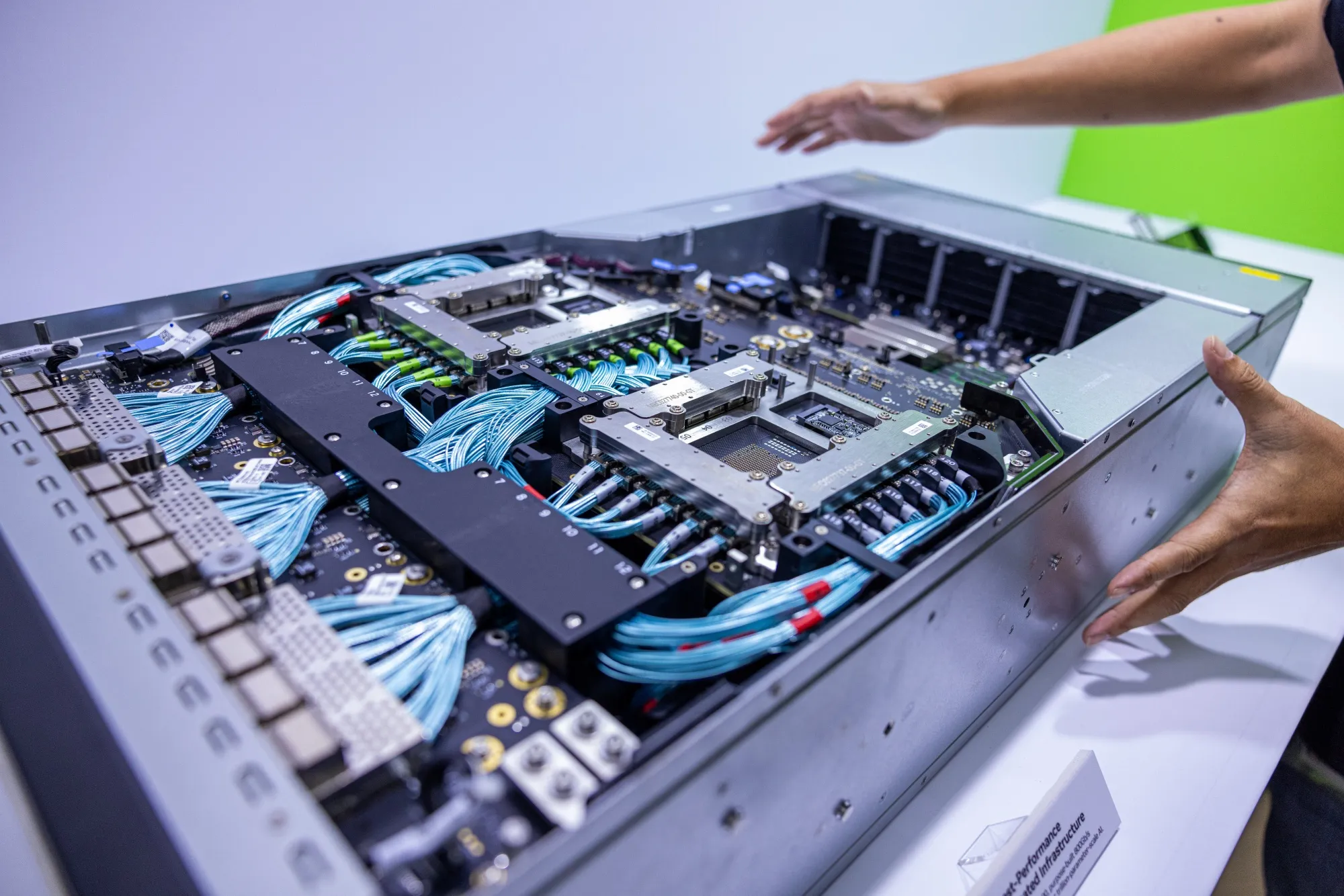

Despite robust order books, the semiconductor ecosystem faces a persistent challenge: production capacity cannot expand overnight. Each advanced lithography system requires years of development, thousands of precision components, and extensive testing.

This reality has created a tension between surging global chip demand and the physical limits of manufacturing expansion. Customers are increasingly securing long-term delivery slots, effectively planning semiconductor capacity several years in advance. While this improves visibility, it also limits flexibility during sudden demand spikes.

Artificial Intelligence as a Demand Multiplier

Artificial intelligence has emerged as one of the most powerful demand multipliers in the semiconductor sector. Training and deploying advanced AI models requires specialized processors fabricated using the most advanced manufacturing techniques available.

As AI adoption accelerates across finance, healthcare, logistics, and defense, global chip demand reflects a growing emphasis on computational density and efficiency. This trend has shifted investment priorities toward high-performance chips rather than mass-market consumer components.

Geopolitical Forces Reshaping Market Access

Semiconductors have moved to the forefront of geopolitical strategy. Export controls, investment restrictions, and technology safeguards now influence how and where advanced chips are produced and sold.

These policies have reshaped global chip demand by redirecting investment toward domestic manufacturing initiatives in Europe, the United States, Japan, and South Korea. While restrictions have introduced uncertainty, they have also triggered unprecedented public funding for semiconductor infrastructure.

Government Policy and Industrial Strategy

Public policy now plays a decisive role in shaping the semiconductor landscape. Governments view advanced chip production as a strategic asset, comparable to energy or defense infrastructure.

In response to global chip demand, national programs are prioritizing supply chain resilience, workforce development, and long-term research funding. These initiatives aim to reduce exposure to external shocks while maintaining access to cutting-edge technology.

Financial Markets and Valuation Pressures

Investor interest in semiconductor companies has surged alongside strategic demand. Firms positioned at critical points in the supply chain command premium valuations, reflecting both their scarcity and importance.

However, expectations tied to global chip demand also raise the stakes. Markets closely scrutinize execution risks, production timelines, and regulatory exposure. Any disruption in delivery schedules or technological roadmaps can have outsized financial consequences.

Supply Chain Resilience Takes Center Stage

Recent years have exposed vulnerabilities in global supply chains, prompting a reevaluation of sourcing strategies. Semiconductor manufacturers now emphasize redundancy, supplier diversification, and regional balance.

Efforts to strengthen resilience are directly linked to global chip demand, which increasingly values reliability over short-term cost efficiency. Long-term contracts and closer supplier partnerships have become standard practice across the industry.

Technological Innovation Beyond Moore’s Law

While Moore’s Law remains a guiding principle, innovation now extends beyond simple transistor scaling. Advanced packaging, heterogeneous integration, and system-level optimization play growing roles in performance gains.

These innovations expand the scope of global chip demand by enabling new applications that were previously impractical due to power or cost constraints. The semiconductor industry is evolving into a more holistic engineering discipline.

Industry Perspective on the Current Cycle

One senior industry analyst summarized the moment by saying,

“This phase represents a fundamental transformation in how demand is defined, where strategic value outweighs unit volume.”

This assessment reflects a broader consensus that semiconductor demand patterns have entered a more stable, infrastructure-driven era.

Workforce and Skills Development Challenges

Meeting future production needs requires more than capital investment. Skilled engineers, technicians, and researchers are essential to operating and advancing semiconductor manufacturing capabilities.

As global chip demand grows, competition for talent has intensified. Educational institutions and governments are expanding training programs to address long-term workforce shortages in advanced manufacturing fields.

Environmental Considerations in Chip Production

Sustainability has become an integral factor in semiconductor strategy. Advanced manufacturing processes consume significant energy and water resources, prompting increased focus on efficiency and environmental impact.

Efforts to align sustainability goals with global chip demand include investments in renewable energy, recycling systems, and more efficient fabrication technologies.

Long-Term Outlook for the Semiconductor Industry

Looking ahead, the semiconductor industry appears positioned for sustained expansion, driven by digital transformation across nearly every sector of the global economy. Demand growth is expected to be steadier, less speculative, and more strategically anchored than in past cycles.

The ability to balance innovation, capacity expansion, and geopolitical complexity will determine how effectively the industry responds to global chip demand in the years ahead.

A Defining Moment for Global Technology Leadership

The convergence of technology, policy, and industrial strategy has made 2026 a defining year for semiconductors. Decisions made today will shape innovation trajectories for decades.

As global chip demand continues to influence economic and security priorities worldwide, the semiconductor sector stands not merely as a supplier of components, but as a cornerstone of modern civilization’s technological foundation.