Austin, Texas, February 11, 2026 — According to Parliament News, that The Apollo humanoid robot has entered a transformative stage of development after securing a 520 million dollar investment that positions the company behind it among the most heavily funded robotics innovators in the United States. The milestone, announced at the company’s headquarters in Austin, signals rising global confidence in intelligent automation and the commercial future of humanoid systems.

The funding round reflects growing momentum across the robotics sector as industries seek flexible, AI driven machines capable of operating in environments designed for people. With this expansion, the Apollo humanoid robot is moving from advanced prototype testing into broader industrial deployment.

Investment Signals Strong Market Confidence

The announcement of large scale funding underscores how seriously investors now view humanoid robotics as a long term economic driver. Backed by major technology and automotive stakeholders, the company aims to scale production capacity and accelerate enterprise partnerships.

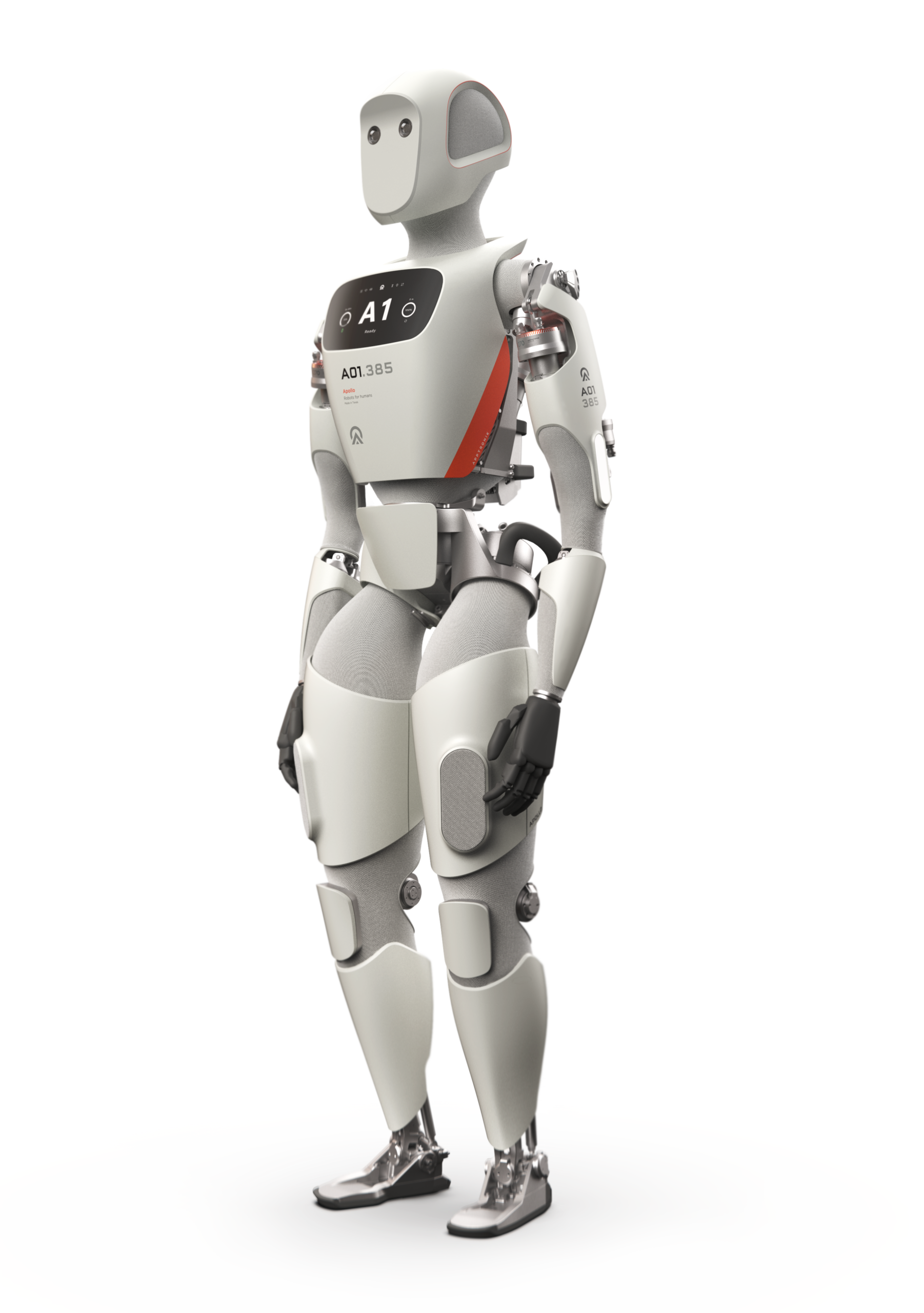

The Apollo humanoid robot stands at the center of this strategy. Designed to bridge artificial intelligence with physical labor support, the platform targets logistics hubs, manufacturing plants, and industrial facilities facing labor shortages and productivity pressures.

Market analysts say the 2026 funding round is one of the largest dedicated to humanoid robotics in North America. This capital injection will support engineering expansion, enhanced testing facilities, and additional hiring across mechanical, electrical, and AI disciplines.

By securing such substantial backing, the Apollo humanoid robot initiative demonstrates that investors believe embodied AI represents the next frontier of automation.

Engineering Designed for Real World Environments

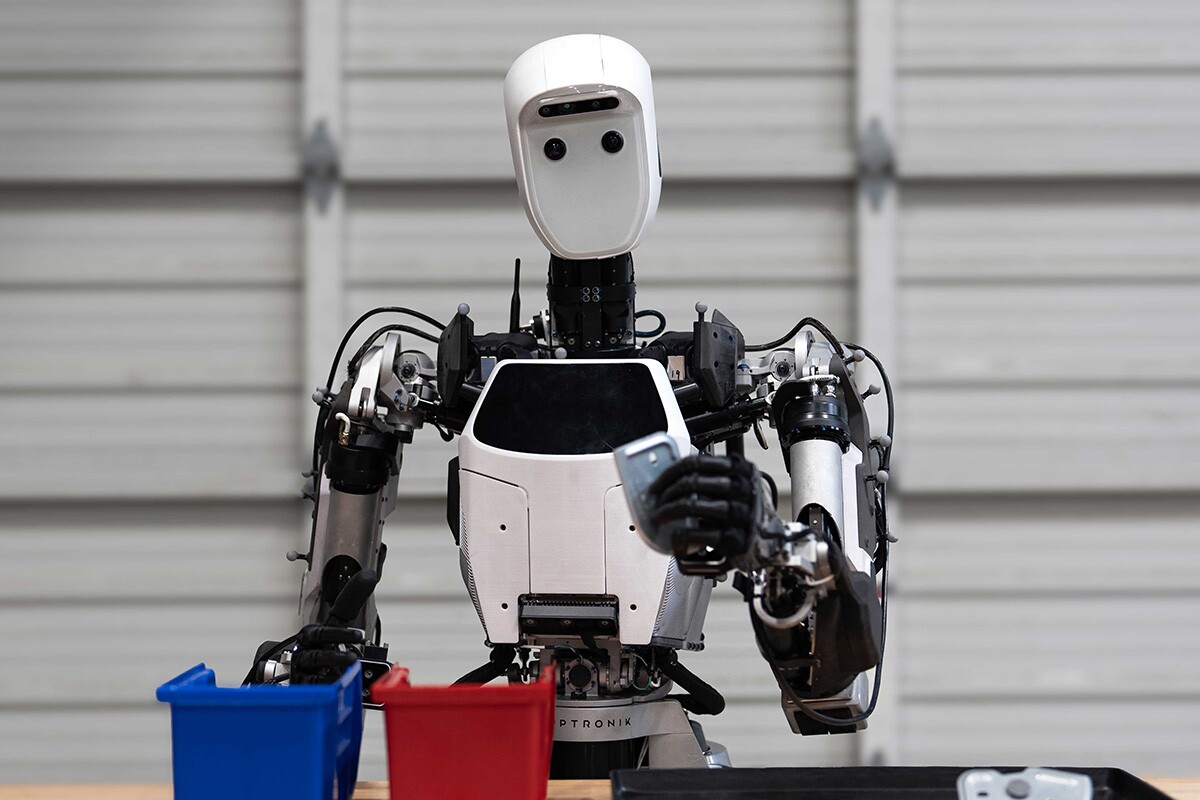

Unlike fixed industrial robots that require customized infrastructure, the Apollo humanoid robot has been engineered to work within existing human built spaces. Its bipedal structure allows it to navigate stairs, hallways, and tight corners while maintaining balance and precision.

Advanced sensor arrays provide spatial awareness, enabling real time adaptation to moving objects and changing surroundings. The robot integrates machine learning systems capable of recognizing patterns in workflow tasks, improving efficiency over time.

Engineers focused on durability and modularity. Components can be replaced or upgraded without redesigning the entire platform. This long term design philosophy aims to reduce lifecycle costs and support enterprise adoption.

The Apollo humanoid robot is also built with safety as a primary consideration. Soft touch materials and controlled motion systems reduce risk during collaborative operations with human workers.

Scaling Production in Austin

The expansion plan includes increased manufacturing capacity at the Austin facility. New assembly lines are being developed to support higher output volumes, while research teams continue refining motion control algorithms and battery efficiency.

Local officials have described the project as a catalyst for regional economic growth. Increased hiring in robotics engineering, AI software development, and systems integration is expected to strengthen Austin’s reputation as a technology innovation hub.

As production scales, the Apollo humanoid robot will undergo extended pilot deployments in warehousing and assembly operations. These pilot programs are designed to gather operational data, measure efficiency gains, and validate commercial viability before full scale rollout.

Executives emphasize that gradual scaling ensures quality control and safety standards remain uncompromised.

Applications Across Industrial Sectors

Logistics remains one of the earliest target markets. Distribution centers often rely on manual labor for sorting, lifting, and transporting goods. The Apollo humanoid robot offers a flexible alternative that can operate without costly redesign of facilities.

Manufacturing plants are also exploring integration opportunities. Because the robot mirrors human form and reach, it can perform repetitive assembly tasks while adapting to evolving production requirements.

Industry observers note that collaborative automation is increasingly preferred over fully autonomous isolation systems. The Apollo humanoid robot is designed to complement human workers rather than replace them, supporting hybrid operational models.

Beyond logistics and manufacturing, future applications could include construction assistance, retail restocking, and hazardous environment support.

Artificial Intelligence at the Core

Artificial intelligence systems serve as the cognitive engine behind the Apollo humanoid robot. Advanced neural networks enable perception, object recognition, and task planning capabilities that evolve through continuous learning.

Cloud connectivity supports performance monitoring and predictive maintenance. This hybrid architecture combines edge processing with centralized analytics, ensuring low latency responses in dynamic environments.

Engineers continue refining algorithms to improve grip precision, load distribution awareness, and navigation stability. Each software update contributes to smoother movements and more reliable task execution.

The Apollo humanoid robot represents a convergence of robotics hardware and AI software innovation that has matured significantly over the past decade.

Workforce Implications and Economic Impact

Automation advancements inevitably raise questions about workforce transformation. Industry leaders involved in the project stress that the primary objective is augmentation rather than replacement.

By handling repetitive lifting and transport tasks, robots can reduce workplace injuries and fatigue. Human employees remain essential for oversight, quality assurance, and complex decision making.

Economic analysts believe intelligent automation may address demographic challenges such as aging workforces and labor shortages in physically demanding roles.

The Apollo humanoid robot could therefore contribute to productivity growth while preserving employment stability through collaborative integration.

Competitive Landscape in 2026

The humanoid robotics field has become increasingly competitive. Several startups and established corporations are racing to achieve scalable deployment.

What differentiates the Apollo humanoid robot is its focused enterprise strategy. Rather than pursuing consumer entertainment or novelty applications, the company prioritizes industrial partnerships that provide measurable economic returns.

Investors have responded positively to this pragmatic approach. Enterprise clients value reliability, safety compliance, and clear productivity metrics over experimental demonstrations.

As global supply chains continue to modernize, the ability to deploy adaptable humanoid systems may become a defining competitive advantage.

Historic Comparison

The current rise of humanoid robotics invites comparison with earlier technological revolutions. In the early twentieth century, assembly line automation transformed manufacturing by standardizing production processes. Later, the introduction of industrial robotic arms reshaped automotive plants and electronics factories.

Today, the Apollo humanoid robot reflects a similar inflection point. Just as programmable logic controllers once revolutionized assembly lines, intelligent humanoid systems may redefine how factories and warehouses operate in the coming decades.

This historic comparison highlights the cyclical nature of innovation. Each generation builds upon previous breakthroughs, blending software intelligence with mechanical precision to unlock new economic potential.

Global Interest and Expansion Prospects

International manufacturers are monitoring developments closely. European and Asian industrial groups have expressed interest in pilot collaborations as regulatory frameworks evolve.

Global deployment will depend on safety certifications, cross border standards, and infrastructure compatibility. The Apollo humanoid robot platform is being engineered with modular compliance features to meet diverse regulatory requirements.

If adoption accelerates abroad, export opportunities could significantly expand the company’s market reach and revenue streams.

Leadership Vision and Long Term Strategy

Company executives maintain that disciplined growth is essential. Rather than rushing into mass production, they emphasize iterative testing and gradual scaling.

One senior executive stated,

“We believe the Apollo humanoid robot represents a turning point in practical automation, and our mission is to deploy it responsibly, safely, and at scale.”

This measured approach aims to balance investor expectations with technological reliability and workforce integration considerations.

Technology, Trust, and Transformation

As humanoid robotics transitions from concept to commercial reality, public perception will play a decisive role. Transparent communication about safety standards, operational limits, and ethical deployment remains critical.

The Apollo humanoid robot symbolizes the broader convergence of artificial intelligence and mechanical engineering. Its continued progress suggests that intelligent machines are becoming more adaptable, collaborative, and industrially relevant.

The coming years will determine whether humanoid platforms achieve widespread enterprise adoption. For now, the substantial 2026 funding round and expansion in Austin underscore the seriousness of this technological evolution.

The journey ahead involves not only engineering excellence but also thoughtful integration into human centered workplaces. If successful, the Apollo humanoid robot may stand as one of the defining industrial innovations of its generation.