Washington, United States – February 13, 2026 — Parliament News — Robotics in aviation are accelerating across the American aerospace sector as manufacturers and airlines intensify modernization efforts to meet record operational demand. Industry leaders say robotics in aviation have moved from experimental tools to essential infrastructure supporting aircraft production, maintenance, and long term safety compliance.

With travel volumes stabilizing at historically high levels, the integration of robotics in aviation is reshaping how aircraft are assembled, inspected, and serviced across the United States.

Surging Demand Reshapes Operational Priorities

The aviation industry in 2026 is defined by elevated fleet utilization and extended aircraft service cycles. Airlines are maximizing operational efficiency while navigating supply chain constraints and tight maintenance schedules.

Manufacturers face production backlogs stretching several years into the future. Engine maintenance facilities report increased inspection frequency due to higher flight hours. In this environment, robotics in aviation offer measurable advantages by reducing bottlenecks and improving process precision.

Automation reduces repetitive strain tasks while maintaining strict adherence to federal safety requirements. The result is a more predictable workflow across manufacturing and overhaul facilities.

Automation on the Factory Floor

Across Washington state and other aerospace hubs, robotic platforms now perform high precision drilling, fastening, and composite application. Aircraft fuselage panels require exact alignment measured in microns. Automated drilling systems ensure consistent spacing and depth, minimizing structural deviations.

Robotic fastening tools apply uniform torque to critical components, reducing the likelihood of mechanical inconsistencies. Sensors embedded within robotic systems provide real time quality feedback, allowing immediate corrections.

Industry executives emphasize that robotics in aviation enhance production consistency while supporting skilled labor rather than replacing it. Technicians oversee automated processes and conduct final inspections to maintain compliance with federal aviation standards.

One aerospace manufacturing executive stated,

“Automation strengthens our capacity to deliver aircraft on schedule while maintaining uncompromising quality.”

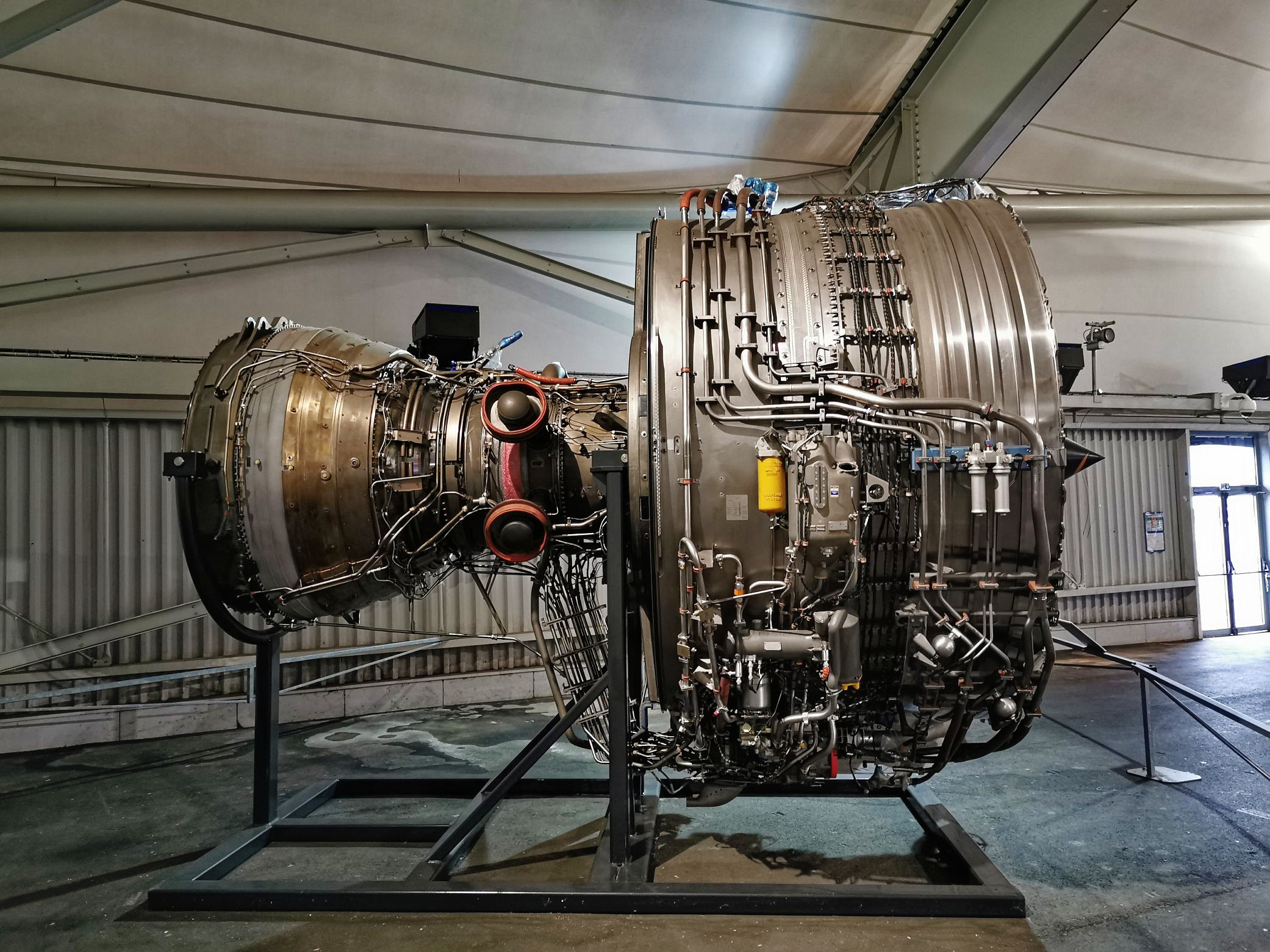

Advanced Engine Inspection and Maintenance

Engine maintenance represents one of the most technically demanding areas in aerospace operations. Turbine blades endure extreme heat and pressure cycles, requiring detailed inspections.

Robotic inspection units equipped with laser scanners and high resolution cameras can access confined engine interiors with greater stability than manual methods. These systems detect microscopic cracks and wear patterns quickly.

Maintenance leaders confirm that robotics in aviation reduce inspection turnaround time while preserving diagnostic accuracy. Technicians analyze robotic data outputs before authorizing repairs or component replacements.

The modernization of engine overhaul facilities reflects broader industry recognition that automation is essential for sustaining high fleet availability.

Regulatory Oversight and Compliance Framework

Federal regulators continue rigorous evaluation of automated systems used in aerospace operations. Each robotic tool undergoes certification processes before full implementation.

Digital documentation generated by automated platforms provides traceable records of every task performed. This enhances audit readiness and strengthens oversight.

A senior aviation compliance official noted,

“Technology improves consistency, but human supervision remains indispensable in safeguarding aviation integrity.”

Robotics in aviation must meet or exceed the reliability benchmarks of traditional manual procedures. Regulatory frameworks are evolving to address software validation and cybersecurity safeguards within automated environments.

Workforce Adaptation and Skills Evolution

As automation expands, workforce roles are evolving rather than disappearing. Aerospace technicians now train in robotics programming, machine interface management, and digital diagnostics.

Educational institutions have incorporated automation modules into aviation engineering programs. Apprenticeships increasingly emphasize collaborative operation between humans and robotic systems.

Industry leaders stress that robotics in aviation create opportunities for advanced technical careers. Robotics maintenance specialists, data analysts, and systems integrators are in growing demand.

This shift underscores the importance of continuous education within a rapidly modernizing sector.

Economic Influence Across the United States

The aerospace sector remains a cornerstone of the U.S. economy. Automation investments strengthen global competitiveness and enhance production reliability.

Robotics in aviation contribute to cost stability by reducing rework and minimizing material waste. Improved throughput allows manufacturers to meet international demand without sacrificing safety.

Financial markets monitor automation expansion as an indicator of operational resilience. Companies adopting advanced systems often demonstrate improved efficiency metrics and stronger long term outlooks.

Washington state, home to major aerospace manufacturing centers, continues to benefit from modernization investments that reinforce regional employment and economic growth.

Sustainability and Resource Optimization

Environmental considerations play an increasingly prominent role in aerospace strategy. Precision manufacturing reduces scrap rates and conserves high value materials.

Automated coating systems apply protective layers evenly, minimizing chemical waste. Predictive maintenance tools extend component life cycles, reducing the need for premature replacement.

By optimizing workflows and minimizing inefficiencies, robotics in aviation indirectly support sustainability objectives within the broader aviation ecosystem.

Competitive Dynamics in Global Aerospace

International competitors are expanding automation initiatives to capture larger shares of global aircraft demand. European and Asian manufacturers continue integrating robotics into their assembly and inspection processes.

The United States maintains leadership through sustained innovation and regulatory compliance. Robotics in aviation provide strategic leverage by balancing production scalability with rigorous safety oversight.

Industry analysts expect global competition to intensify as travel demand remains elevated through the remainder of the decade.

Evolution of Robotics in Aviation

Automation in aerospace manufacturing traces back to early computer numerical control systems introduced decades ago. Over time, robotic arms became capable of handling delicate composite materials and high precision drilling.

The evolution accelerated with advancements in sensor technology and artificial intelligence. Modern robotics in aviation integrate predictive analytics, allowing systems to adapt dynamically during operations.

This progression reflects a gradual transition from supportive automation to integrated digital ecosystems shaping every stage of aircraft production and maintenance.

Strategic Outlook Through the End of the Decade

Industry forecasts suggest automation adoption will continue expanding. Artificial intelligence driven diagnostics may anticipate component fatigue before visible wear appears.

Collaborative robotic systems designed to operate safely alongside technicians are becoming more common in maintenance hangars. Data integration platforms allow real time monitoring across fleets.

An aerospace strategy executive commented,

“Our future depends on integrating innovation responsibly while preserving the trust passengers place in aviation safety.”

Robotics in aviation are positioned to remain central to modernization efforts as the industry balances growth with accountability.

Structural Transformation of Aerospace Operations

The acceleration of robotics in aviation represents a structural transformation rather than a temporary adjustment. Manufacturing precision, maintenance reliability, regulatory documentation, and workforce development now intersect within digital automation frameworks.

Airlines benefit from improved fleet availability and predictable service intervals. Manufacturers achieve consistent production output. Regulators gain comprehensive digital traceability.

As 2026 unfolds, Washington and other aerospace hubs continue strengthening infrastructure through automation investment. Robotics in aviation have become foundational to sustaining efficiency, safety, and economic competitiveness.

The ongoing integration of intelligent systems with human expertise signals a durable shift in how aerospace operations will function for years to come.